You may not have heard of metallography, but if you’ve used a phone, been on a plane, or rode in a car, you have benefitted from its existence. Metallography is defined as “the study of the atomic and chemical structure of all types of metallic alloys using microscopy.” It traces its roots back to 19th-century British scientist Henry Clifton Sorby, but advances in technology have helped it maintain relevance and led to new discoveries about the properties of metals.

Why Do We Need Metallography?

Modern industries use information learned through metallography to inform the decision-making that shapes their products. Metallography helps companies decide which materials are stable enough to build bridges or construct cars and motorcycles with. Since it mainly looks at how the microstructure of metals contributes to their performance, modern companies and manufacturers use it as a form of quality assurance. Metallography can ensure that the right metal is used for crucial things like cars, planes, and electronics.

Metallography is also crucial in aiding the development of new materials. There are thousands of standardized alloys available today, and even more in development as demand for lighter and stronger metals continues. Examining alloys on a microscopic scale can reveal a lot about their macroscopic properties, and this knowledge is utilized heavily in an alloy’s design, development, and production.

Metallographic Techniques to Evaluate the Microstructure of Metals

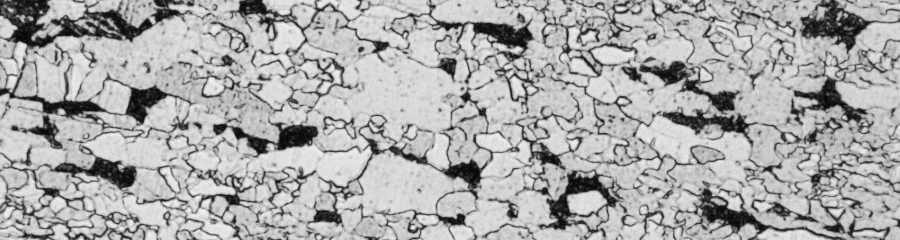

Several different metallographic techniques are used to determine the microstructure of metals. Light microscopy in brightfield (BF) mode is the most commonly used method. Other metallographic techniques include darkfield illumination, differential interference contrast (DIC), and color etching.

- With brightfield (BF) illumination, light from the top of the microscope is poured down onto the specimen. This light is then reflected off the sample, and an image is sent to the eyepiece or camera for observation. This technique is considered the simplest, which is why it is commonly used.

- While darkfield (DF) microscopy is less well known, it is still a powerful technique for examining the microstructure of alloys. With this method, the specimen is illuminated indirectly, allowing for a lower intensity of light that makes it easier to see more minor imperfections.

- Differential interference contrast (DIC) uses a prism, a polarizer, and an analyzer to examine the height differences on the specimen surface.

- While the color of microstructures does not offer valuable information in most metallographic applications, they are sometimes necessary. In these instances, color etching is useful. Tint etchants are applied chemically or electrochemically, and they create a thin film on the surface of the specimen. Light from the microscope reflects off this film to reveal additional features in the microstructure of some commercial alloys, such as Fe, Cu, and Al.

The Importance of Proper Analysis of the Microstructure of Metals

Many industries rely on proper metallographic analysis of material before moving forward with production. Because it’s so crucial for the metal to have been processed correctly, the specimen must be prepped and examined carefully to ensure there are no errors introduced during observation.

Proper specimen preparation includes selecting a representative sample and sectioning, grounding, and polishing this sample to allow the material’s microstructure to be revealed through etching. Scientists must also ensure the specimen does not contain any polishing scratches or pits and is flat enough to examine at high magnification. Finally, they need to be careful not to over-etch the sample; otherwise, they risk ruining the microstructural detail revealed.

How Does Microstructure Correlate With Physical Properties?

Over the years, scientists have discovered that several rules of thumb can be applied to most metals when examining their microstructure.

- Decreased grain size is associated with higher yield strength and hardness.

- Ductility is lower in metals with a higher inclusion rating.

- Inclusion content and distribution directly influence a metal’s cracking rates and fracture resistance.

- Inconsistencies or “discontinuities” in a metal’s microstructure are associated with failure sites, or the spot where the metal breaks.

Understanding what microstructure can tell us about a metal’s physical properties can help us predict how it will perform in different situations. Identifying certain traits and inconsistencies can help manufacturers avoid choosing the wrong material and putting potentially dangerous or defective products into circulation.

What Is the Difference Between Metallurgy and Metallography?

Hopefully, at this point, you have a solid understanding of what metallography is and why it’s important. Now, you may be curious about the difference between metallography and metallurgy. While metallography is the study of the structure of an alloy using microscopic techniques, metallurgy is the process of recovering metals and seeing how reactive they are. The metallurgical evaluation also involves microscopy, specifically the use of metallurgical microscopes.

Materials Science Microscopes From UNITRON

Metallography serves a unique and important purpose in helping scientists develop and test new alloys, and it would not be possible without microscope technology. To learn more about metallography, materials science microscopes, and all their applications, contact the experts at UNITRON today.